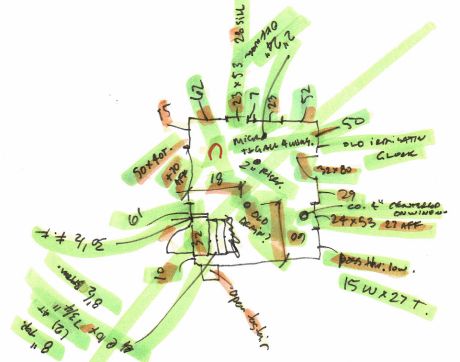

Step 1 - THE OVERALL - Note red notes to myself, and area that is circled.

Step 2 - THE SPECIFIC Note items are highlighted out in two colors. My drafter had one color, I had another.

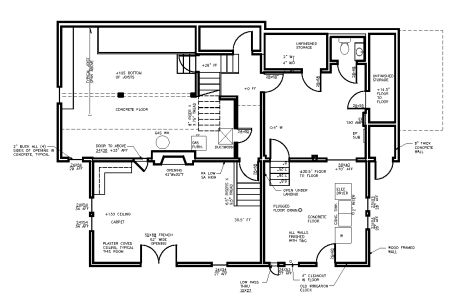

Step 5 - ENTERED IN CAD

how i do interior as-builts

october

9, 2015 simple

screen doors october

14, 2013 The

frames are all glued up with biscuits

at the corners - like simple frames.

Painted on the outside, clear

sealed on the inside. The material

is 1" thick to accomodate

the narrowest lock mechanism I

could find. The

screens are stopped in with dainty

wood trim held in place using

a pin nailer - stretching the

screen tight as you go. Excess

trimmed off. They

survived two years of children

pushing on the lower panel before

we had to reinstall the screen.

Not to bad.

I do quite a bit of projects that start without drawings, and need a

good base before design starts. That means going to into the field

for a day recording measurements for an entire building, then taking the info back to the

office to draw up proportionally in cad. I'm generally accurate within 2".

Going back to the jobsite repeatedly is a waste of time and client fee, so

getting all the info the first time is important to me.

I record all my measurements in inches, no fractions,

measured to the wall, not the trim.

Feet is always apprebreviated FT.

6 and 9 are underlined. (Is it 191 or 161?)

BEFORE I start, I photograph EVERY room's wall, ceiling, and floor. It

helps to have a photo to look back on for misc details.

Step 1 - THE OVERALL. Draw up a sketch of the overall

floor level. It can be loose and sketchy with mistakes scribbled out. We're

collecting data here, not making art.

a. Get some overall dimesions all

the way across the building, wherever possible.

b. Dimension each room's length and width.

c. Get each rooms

ceiling height.

Step 2 - THE SPECIFIC. On a new sheet of paper, draw

up the perimeter walls of the space or room, and measure each wall segment

and door segment. I measure to the inside of interior window jambs and the

leaf of each door. Each room gets its own sheet of paper.

Step 3 - THE DETAILS. Add misc. details to each room,

floor and ceiling registers, outlets, switches.

Step 4 - ASSEMBLIES. Measure a couple pieces of trim,

siding, the width of door jambs, some sill heights, ceiling and floor tile.

Step 5 - ENTERING IN CAD. I start with my overall

drawing and get the proportions right, and then fill in the detail. If its

within 2", I feel like I'm doing really good.

a. as you work, highlight

off each dimension that has been entered. If its suspect, circle it in a

separate color.

After looking around a screen

doors, I decided to make my

own out of some of the fir framing

from my own house remodel.